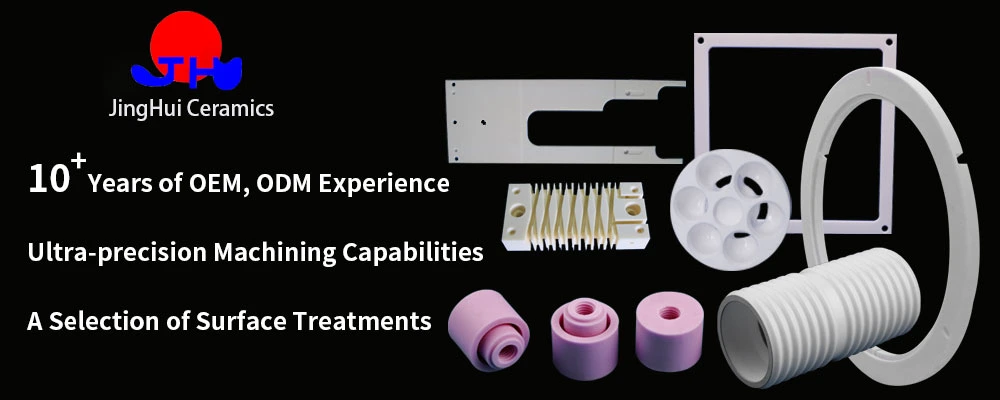

Machine Semiconductor High Purity Alumina Ceramic Parts

Overview Machine Semiconductor High Purity Alumina Ceramic PartsProduct Description The specification of industrial cera

Overview

The accuracy achieved after precision machining

(1) Axis: roundness 0.002 mm, concentricity 0.002 mm, smoothness Ra0.1;(2) Hole: the minimum processing hole diameter is 0.2 mm and the depth is up to 6mm;(3) Slot: min. value to be 0.1 mm of narrow groove, and grooves with custom shapes;(4) Plane: 0.1mm sheet with minimum processable thickness, parallelism 0.001mm, measurement tolerance 0.001 mm, finish Ra0.1; (5) Thread: The minimum machinable M2 internal thread, the accuracy of GB-7h, the external thread size is not limited, the accuracy is GB-6g.

The main characteristics of the technical ceramic parts1. offer different grade dimensional accuracy2. One of the cost-effective ceramic parts3.. High hardness up to 1700 HV,4.Super compressive up to 2240 Mpa5. High heat resistance6. Good wear resistance7. High electrical resistivity8. High corrosion resistance9. Support customized specification, service

The description of alumina ceramic parts

Aluminum oxide (Alumina) has an extensive application due to its versatility and low cost of material than other advanced ceramics. Alumina offers high electrical insulation resistance, high-temperature resistance, strong hardness, wear resistance, and good chemical stability, making it a good material to withstand high temperature and chemical corrosion.Our factory produces a selection of purity of alumina from 75% to 99.8%, all of the ceramic parts we supplied are with a dense body via dry pressing, hot pressing, ceramic injection molding, and ISO pressing. In order to achieve some special application for fitting, reducing the friction, increasing the insulation, we provide a serial of secondary processes after sintering, covering CNC machining, polishing, glazing, and metalizing.We manufacture a wide range of alumina ceramic rings, including ceramic tubes, ceramic rings, ceramic discs, ceramic rods, ceramic arms, ceramic wire guides. Whatever, it's a prototyping case, or high volume demand, we believe we are able to provide you with a desirable solution.

Typical Applications

Why choose us?

A: Sure, the sample is free and freight collect.Q3: When will you ship it?

A: If the products are in storage, we'll ship within 48 hoursQ4: When can I get the price?

A: We regularly quote within 12 hours after we get your inquiry. If you are in urgent need of getting the price.Please call us or tell us in your email so that we will proceed with your inquiry as a priority.Q5: Is it available to provide customized products?

A: We always support custom-made demand as per different materials, dimensions, and designs.Q6: How to ensure quality?

A: The dimension out of any batch will be carried out sampling inspection per international AQL standard.A 100% cosmetic inspection will be done.

Basic Info.

| Model NO. | Customized |

| Certificate | RoHS, Reach, ISO9001 |

| Usage | Advanced Ceramic Parts |

| Features | High Precision, High Insulation |

| Grade of Material | 96%, 99%, 99.5% Alumina |

| Density | Over 3.65g/cm3 |

| Color | White, Pink, Ivory, Black |

| Forming Method | Dry Pressed, ISO Pressed, Hot Pressed |

| Product Name | Ceramic Parts |

| Transport Package | Individual Packaging |

| Specification | Max. 800mm mmx 1000mm x 30mm |

| Trademark | JingHui |

| Origin | China |

| HS Code | 8547100000 |

| Production Capacity | 500000/Month |

Product Description

Machine Semiconductor High Purity Alumina Ceramic PartsProduct Description

| Optional Materials | alumina, zirconia, silicon carbide, silicon nitride, steatite optional |

| Outer diameter | 0.5 ~800 mm |

| Length | 1~1000mm |

| Roughness | To be Ra0.05 |

| Surface treatment | Polished, Glazed, Metalized availability |

| Cosmetic | Smooth surface without contamination, deformation, and crack |

The accuracy achieved after precision machining

(1) Axis: roundness 0.002 mm, concentricity 0.002 mm, smoothness Ra0.1;(2) Hole: the minimum processing hole diameter is 0.2 mm and the depth is up to 6mm;(3) Slot: min. value to be 0.1 mm of narrow groove, and grooves with custom shapes;(4) Plane: 0.1mm sheet with minimum processable thickness, parallelism 0.001mm, measurement tolerance 0.001 mm, finish Ra0.1; (5) Thread: The minimum machinable M2 internal thread, the accuracy of GB-7h, the external thread size is not limited, the accuracy is GB-6g.

The main characteristics of the technical ceramic parts1. offer different grade dimensional accuracy2. One of the cost-effective ceramic parts3.. High hardness up to 1700 HV,4.Super compressive up to 2240 Mpa5. High heat resistance6. Good wear resistance7. High electrical resistivity8. High corrosion resistance9. Support customized specification, service

The description of alumina ceramic parts

Aluminum oxide (Alumina) has an extensive application due to its versatility and low cost of material than other advanced ceramics. Alumina offers high electrical insulation resistance, high-temperature resistance, strong hardness, wear resistance, and good chemical stability, making it a good material to withstand high temperature and chemical corrosion.Our factory produces a selection of purity of alumina from 75% to 99.8%, all of the ceramic parts we supplied are with a dense body via dry pressing, hot pressing, ceramic injection molding, and ISO pressing. In order to achieve some special application for fitting, reducing the friction, increasing the insulation, we provide a serial of secondary processes after sintering, covering CNC machining, polishing, glazing, and metalizing.We manufacture a wide range of alumina ceramic rings, including ceramic tubes, ceramic rings, ceramic discs, ceramic rods, ceramic arms, ceramic wire guides. Whatever, it's a prototyping case, or high volume demand, we believe we are able to provide you with a desirable solution.

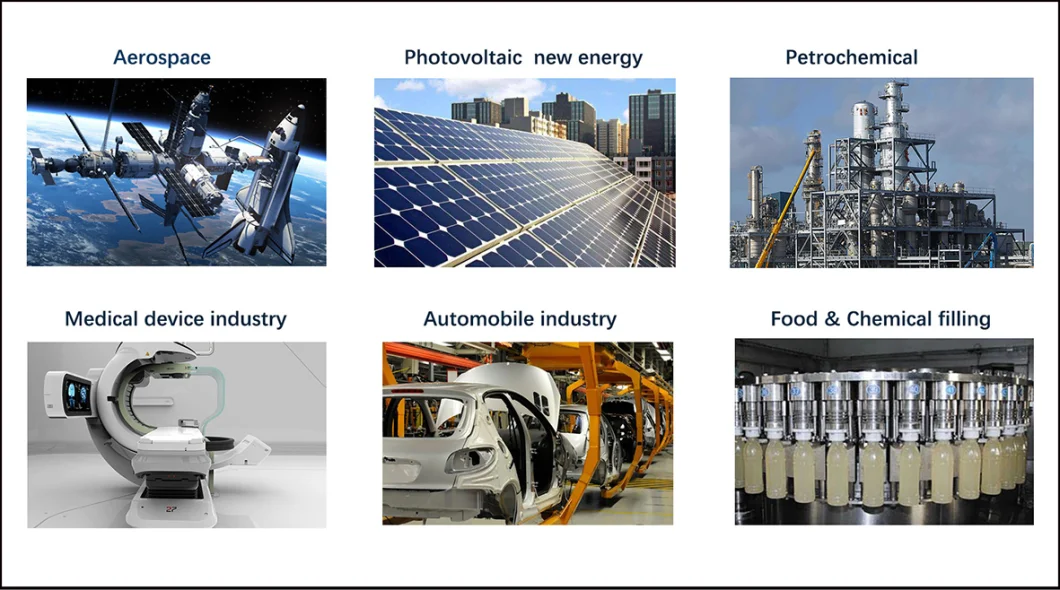

Typical Applications

The application of alumina ceramic parts

Remark:

We produce a series of alumina ceramic products, including alumina metalized ceramics, ceramic substrates, ceramic wafers, ceramic guides, and so on.Product ParametersDatasheet of technical ceramic materials

| Property | Units | Materials | ||||

| 99.5%Al2O3 | 99%Al2O3 | 95%Al2O3 | ZrO2 | Si3N4 | ||

| Density | g/cm3 | ≥3.85 | ≥3.80 | ≥3.60 | ≥6.0 | ≥3.2 |

| Water absorption | % | 0 | 0 | 0 | 0 | 0 |

| Hardness | HV | 1700 | 1700 | 1500 | 1300 | 1550 |

| Flexural strength | Mpa | ≥379 | ≥338 | ≥320 | ≥1200 | ≥600 |

| Compressive strength | Mpa | ≥2240 | ≥2240 | ≥2000 | ≥1990 | ≥2500 |

| Fracture toughness | Mpa m1/2 | 4-5 | 4-5 | 3-4 | 6.5-8 | 6 |

| Max. service temperature(Non-loading) | ºC | 1675 | 1600 | 1500 | 1000 | 1200 |

| CTE (20-800ºC) | 1×10 -6 /ºC | 6.5~8.0 | 6.2~8.0 | 5.0~8.0 | 8.0~9.5 | 3.1 |

| Thermal shock | T(ºC) | ≥250 | ≥200 | ≥220 | ≥300 | ≤1000 |

| Thermal conductivity(25ºC) | W/m.k | 30 | 29 | 24 | 3 | 15~20 |

| Volume resistivity (25ºC ) | ohm.cm | >1 x 10 14 | >1 x 10 14 | >1 x 10 14 | >1 x 10 11 | >1 x 10 12 |

| Insulation strength | KV/mm | 19 | 18 | 18 | 17 | |

| Dielectric constant(1Mhz) | (E) | 9.7 | 9.5 | 9.5 | 29 | |

1. Powerful R&D to support the customized specification, also large-scale mass production capability2. In-house complete manufacturing equipment, including forming, sintering, precision machining process. 3. Rigorous quality control system and processes per ISO9001: 2008, including IQC, IPQC, QA, OQC4. Surpassing pre-sales and after-sales service, everything we do just for the business growth of our customers.

Certifications

Q1. Are you a factory or trading company?

A: We are a manufacturer. You are welcome to visit our factory.Q2: Do you send a sample to check?A: Sure, the sample is free and freight collect.Q3: When will you ship it?

A: If the products are in storage, we'll ship within 48 hoursQ4: When can I get the price?

A: We regularly quote within 12 hours after we get your inquiry. If you are in urgent need of getting the price.Please call us or tell us in your email so that we will proceed with your inquiry as a priority.Q5: Is it available to provide customized products?

A: We always support custom-made demand as per different materials, dimensions, and designs.Q6: How to ensure quality?

A: The dimension out of any batch will be carried out sampling inspection per international AQL standard.A 100% cosmetic inspection will be done.

Send to us